Spunlace nonwoven fabric is a type of non-woven material that is produced by entangling and bonding fibers mechanically, thermally or chemically.

There are four types of spunlace nonwovens that are widely used in a variety of industries including industrial wipes, civil wipes, medical materials and beauty nonwovens. These include plain, aperture, embossed and some chemical treated spunlace roll goods.

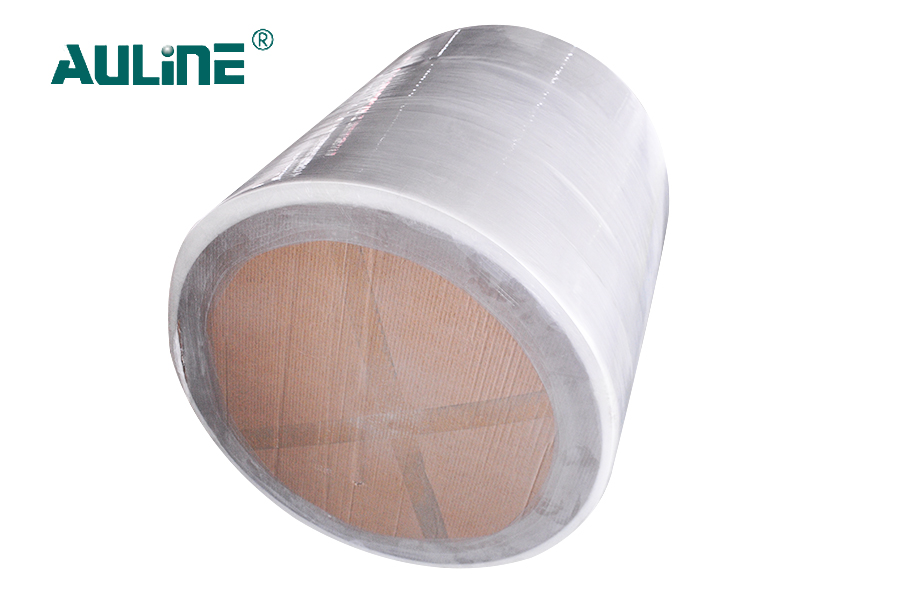

Dual Textured Woodpulp/PP

Spunlace nonwoven fabric is a kind of non-woven material, which is derived by the process of spraying fine water jets onto one or more layers of fiber webs to entangle them and strengthen their strength. It is made of various types of fiber raw materials, such as polyester, nylon, polypropylene, viscose fiber, chitin fiber, superfine fiber, lyocell, silk, bamboo fiber and wood pulp fiber.

Dual Textured Woodpulp/PP is a high-performance wiper that combines the cleaning power of wood pulp with the softness of polypropylene. It has an embossed texture pattern that provides special cleaning capabilities in difficult-to-handle dirt environments.

This nonwoven fabric is ideal for hand wiping and hard surface wiping, especially in areas where fluids must be released in metered amounts or where lint is a concern. It is also well suited for industry cleaning, equipment maintenance, dental clinics and other applications that require high strength and low lint. It is also resistant to heat and abrasion.

Flushable & Fully Degradable

As the demand for consumer wipes rises, manufacturers and private labelers are seeking alternatives to traditional disposables that are environmentally friendly. The latest products from leading brands include biodegradable, compostable and fully flushable choices with a range of performance factors.

These new nonwovens incorporate appropriate fibers in a modified airlaid, hydroentanglement or combination process that is based on less basis weight, more softness and sustainable design. This enables producers to sell softer, greener, more sustainable hygiene products at a price premium.

Spunlace nonwovens can be manufactured from a variety of raw materials such as polyester, polypropylene, viscose, bamboo fiber and bicomponent fiber. They can be produced in different thicknesses, lengths and weave structures to meet customer requirements and application needs.

Bamboo

Plain Spunlace Nonwoven is a very common choice for wet wipes, diapers and other sanitary products. It comes in a variety of sizes, colors and designs to meet the demands of customers across the globe.

Generally speaking, spunlace nonwoven is made of a variety of raw materials such as adhesive, terylene, bi-component fiber, bamboo fiber and tencel fiber, etc. It is the combination of a few major components including carding and sizing, impurity removal, fiber web formation, and finishing processes that makes it possible to produce the best of breed spunlace nonwovens that are both environmentally sound and competitively priced.

A reputable supplier will not only offer the most efficient production process, but also provide an extensive range of products and services to ensure that you get what you pay for. It is a good idea to do your homework before choosing a supplier. This way, you can be sure to receive a top-notch product at a price that will keep your business afloat.

Woodpulp/PET

Plain Spunlace Nonwoven are the most common type of nonwoven fabrics, which can be made with a variety of fibers such as polyester, nylon, polypropylene, viscose, chitin, superfine fibre, silk, wood pulp and bamboo. They are also available in a wide range of color and pattern designs.

A spunlace nonwoven fabric is made by entangling loose fibers through multiple rows of jets of water at high pressure to drill entangled tissue and its cross fibers, giving them an isotropic characteristic. This process reinforces the fibers, and makes them strong enough to withstand heavy industrial and automotive applications.

The fabric is soft, skin-friendly and super absorbent, and is able to resist lint and solvents. It is popularly used in the production of wet wipes and other products. It is a high-quality, low lint and solvent-resistant material, and can be produced in plain, mesh or embossed patterns. It is suitable for all types of wet wipes and other wiping needs.